Mitigating The Shaking: Seismic technology key to reducing induced seismicity

- Published: Friday, 19 February 2016

- Author: Jim Bentein

Between 2005 and 2008, there were eight earthquakes registering magnitude 3.0 or greater in Oklahoma. In 2013, that number climbed to 109, and in 2014, to 584. By late November 2015, there were 802 recorded by the Oklahoma Geological Survey—more each day than were recorded each year in the earlier period—and the once quiet state had surpassed California as the most seismically active continental U.S. state.

In recent months, the quakes have caused additional alarm due to their proximity to the massive Cushing crude oil storage hub, one of the largest in the world. Increasingly, authorities have ordered a cessation or reduction in injection rates of wastewater in nearby wells as a result.

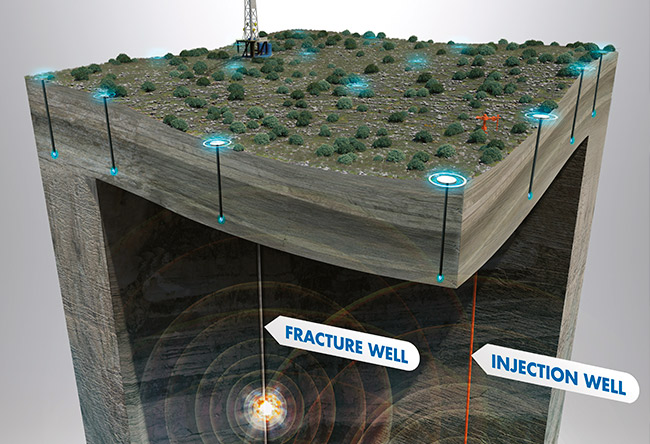

SEISMIC ALERT ARRAY MicroSeismic’s seismicity monitoring system allows operators to establish a baseline for naturally occurring seismicity prior to the start-up of injection activities. Monitoring over the life of the asset helps to demonstrate proactive stewardship of field operations. (IMAGE: MICROSEISMIC INC.)

SEISMIC ALERT ARRAY MicroSeismic’s seismicity monitoring system allows operators to establish a baseline for naturally occurring seismicity prior to the start-up of injection activities. Monitoring over the life of the asset helps to demonstrate proactive stewardship of field operations. (IMAGE: MICROSEISMIC INC.)

Similarly, the area around Fox Creek, Alta., northwest of Edmonton, typically recorded one or two small quakes per year until recently, when increasing frequent and intense seismic events have risen in tandem with hydraulic fracturing in the Duvernay Formation. There have been more than 160 earthquakes since 2013, including two in 2015 of magnitude 4.4 that the Alberta Energy Regulator (AER) has attributed to hydraulic fracturing, making them among the strongest ever to be connected to fracking.

And the B.C. Oil and Gas Commission in 2014 positively linked 231 seismic events over 14 months to the shale gas sector, with some causing damage to horizontal wellbores. In August 2014, a 4.4 magnitude earthquake was recorded in northeastern B.C. that the commission found was “triggered by fluid injection during hydraulic fracturing.” A year later, on Aug. 17, 2015, Progress Energy temporarily shut down multistage fracturing operations in the Montney shale when a magnitude 4.5 quake struck three kilometres from their well, in an area about 100 kilometres northwest of Fort St. John, B.C.

In most cases, the increased seismic activity has coincided with the rise in shale gas and tight oil production, which require massive hydraulic fracturing to release the hydrocarbons. But while hydraulic fracturing has sometimes been blamed, it is usually the large-scale injection of wastewater—both the return to surface of water pumped for the frac and highly saline formation water—into deep formations that has been associated with induced seismicity.

SMALL NUMBERS

While waste-water-injection-related earthquakes may appear alarming, Peter Duncan, founder and co-chair of MicroSeismic, a Houston-based company specializing in hydraulic fracture stimulation surveillance and evaluation, points out that they still represent only a tiny fraction of wells in operation and that the technology exists to mitigate the risk—where it is used.

“Of some 150,000 wells injecting a couple of million barrels a day [of waste water] all over the U.S., you have only a handful of instances where there are earthquakes or induced seismicity that have been large enough to be felt,” he notes. “And if you are monitoring and you sense that the events are larger, you can shut the whole system down very readily. It is a pretty well understood engineering process in that we can mitigate that risk by simply flowing back the well. And I would emphasize that regulations are coming in places that make sense [to enact them], and those have been fairly successful at mitigating the risks.”

Last February, the AER introduced seismic monitoring and reporting requirements for operators in response to concerns over induced seismicity in the Fox Creek area. Similar to that enacted earlier in B.C., the AER adopted a traffic light protocol that sets thresholds for reporting seismic activity. Any events measuring a magnitude of 2.0 to 3.9 must be reported, and companies must modify their operations to help prevent future events. Any event that measures 4.0, the magnitude at which the quake is likely to be felt at the surface, prompts a shutdown of operations within a five-kilometre radius, regardless of whether or not they are considered the cause, until mitigation measures are agreed upon.

The U.K. has required monitoring of fracturing and wastewater injection since experiencing quakes a few years ago, Duncan says, and Ohio more recently enacted monitoring requirements for injection wells. In Oklahoma, which remains largely unregulated, deep well disposal of waste water has been occurring for decades, and until recently, there was a reluctance to blame the booming unconventional oil and gas industry for the surge in earthquakes.

Companies that specialize in seismic technology, like MicroSeismic, which mostly monitors fracking operations to help companies improve their effectiveness, and Weir-Jones Group in Vancouver, which has specialized in monitoring natural earthquakes for decades, now offer induced seismicity monitoring specific to fracturing and water injection.

As three dimensional seismic has become more common, it is also possible to determine where naturally occurring fractures are and avoid them, though legacy injection wells were drilled prior to that ability becoming widely available.

THE CAUSE

There are generally four factors that need to be in place for a large seismic event to be induced, says Duncan. “There has to be a pre-existing fault under a certain amount of stress; the fault has to be orientated in the right direction; it has to be deep enough that it can slip over a large area; and there has to be a sufficient amount of fluid under sufficient pressure going in but not escaping fast enough—if the fluid leaks off, the pressure goes away and the fault is not lubricated.

“It’s like hydroplaning with a car’s tires—when you get a slick of water on the road the tire can lose contact with the road because it’s riding on that slick of water. Because the water is incompressible, that thin film of water overcomes the friction that would otherwise be there.”

MicroSeismic’s passive seismic system, which can be incorporated in its BuriedArray system or used as a stand-alone sparse array for real-time seismicity monitoring, will detect an increase in magnitude of events early on so that action can be taken to forestall larger events. “We always see build-up of smaller events first, and when you see smaller events are getting larger, then if you reverse the pumping process you are going to remove the fluid from the fault and the tectonic forces shut it down again.”

Highly sensitive frac monitoring systems typically pick up events at around minus two on the Richter scale—roughly equivalent to the shock created by dropping a can of pop on a cement floor from waist level, says Duncan. (Since modern seismographs can detect seismic waves smaller than those originally chosen for zero magnitude, the scale now measures earthquakes having negative magnitudes. Each number represents a 10-fold difference in magnitude.)

Because felt seismic events are exponentially stronger, systems to monitor them require fewer ground stations and less data processing, and are therefore much cheaper to install and operate. “To put it into perspective, if we are putting in a BuriedArray [hydraulic fracture monitoring system] we will typically have two or three stations per square kilometre, whereas if you were putting in an array simply to look for the larger events, you can get away with one station every four or five kilometres.”

SEISMIC MONITORING EVOLUTION

In Canada, there may not be any company better suited to have come up with a cost-effective technology to monitor seismic events caused by fracking than Weir-Jones Group. That’s because the privately owned company, founded in 1971 by Iain Weir-Jones, who remains its president, is widely known for its expertise in monitoring seismic events ranging from possible earthquakes to rockfalls to monitoring the integrity of nuclear power plants where seismic events might occur.

The origin of the company’s suite of technologies is systems developed to provide a warning system before a quake strikes and another that measures the structural integrity of buildings, bridges and other structures after a quake has hit.

A newer product, which it has started marketing in the last few months, is its QuakeMonitor system developed specifically for induced seismicity monitoring, working within the ranges of magnitudes applicable for frac monitoring and regulatory compliance of 0.5 magnitude and larger. Given the controversy over seismic events caused by fracking, Weir-Jones says the new technology offers a cost-effective approach for producers to conduct ongoing monitoring of their wells.

He says QuakeMonitor is a low-cost and highly effective solution for companies concerned about seismicity at their sites. The capital cost of installing one device is $8,500, while continuous monitoring, either by satellite or cellular technology, costs about $1,000 monthly. That compares to fracture mapping microseismic systems that often run from $250,000 to $400,000, he says. “We can install the system in two hours or less,” he said. “Some of the other [competitive] systems cost 10 times that to install and they amount to overkill.”

He said there was a time in the past when surface-based systems were not as reliable as higher cost technology installed inside a reservoir, “but the software and hardware [of his company’s surface-based system] has improved dramatically.”

The last few decades have seen a huge evolution in the technology that, with state-of-the-art digital recorders, triaxial downhole sensor packages and real-time data rendering, has created the ability to monitor geo-mechanical events to depths greater than 10,000 feet. A single station can now provide seismic magnitudes, event distance from the well and seismicity rates and report it to the operator in seconds, he says, while three or more stations can add location to reporting and reduce the chance of false alarms.

“QuakeMonitor tells the operator what is happening around his frac,” Weir-Jones says. “It tells him if a seismic event happened four kilometres away and is not on his site. It uses a sophisticated algorithm to listen for deep-seated events.”

He says if he was an operator in an area where seismic events can occur, he would have more than one system installed, which would provide an operator with a level of protection normally only achieved with much more costly systems. There has been a great deal of interest in the new offering, he says.

By Jim Bentein and Maurice Smith

-NTM-